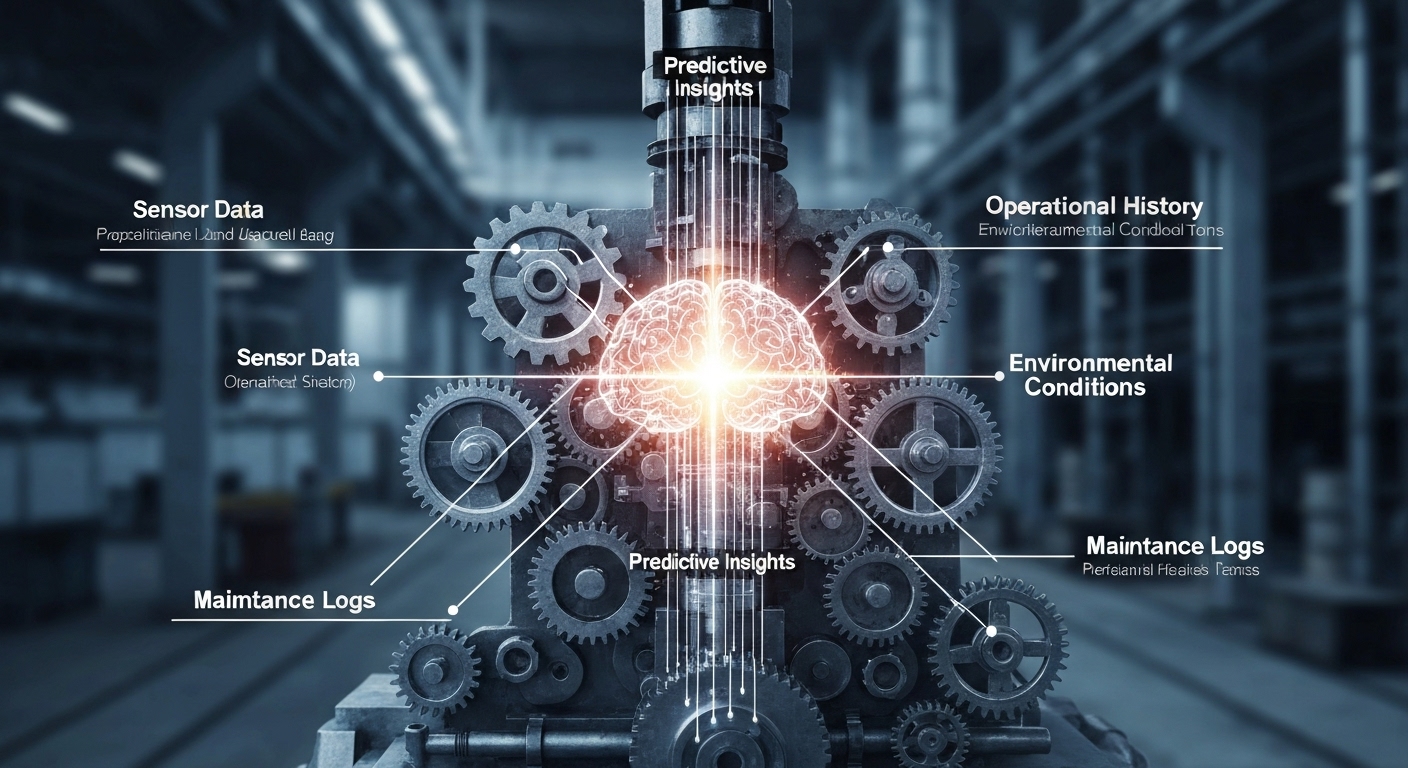

Machine Learning for Predictive Maintenance : A Comprehensive Guide

Machine learning for predictive maintenance is transforming industries by enabling businesses to anticipate equipment failures and optimize maintenance schedules. This proactive approach reduces downtime, minimizes costs, and extends the lifespan of valuable assets.

What is Predictive Maintenance and Why Use Machine Learning?

Predictive maintenance uses data analysis and machine learning to predict when equipment is likely to fail. Instead of relying on fixed maintenance schedules or reactive repairs, predictive maintenance allows for interventions only when necessary, based on real-time condition monitoring. Traditional methods often lead to either unnecessary maintenance or catastrophic failures. Machine learning offers a powerful solution by uncovering complex patterns in data that humans might miss.

Benefits of Machine Learning in Predictive Maintenance

- Reduced Downtime: By predicting failures, maintenance can be scheduled proactively, minimizing disruptions to operations.

- Cost Savings: Less frequent maintenance and fewer unexpected breakdowns translate into significant cost reductions.

- Extended Asset Lifespan: Optimized maintenance ensures equipment operates at peak efficiency for longer.

- Improved Safety: Preventing equipment failures reduces the risk of accidents and injuries.

- Increased Efficiency: Maintenance teams can focus on critical issues, improving overall operational efficiency.

Key Machine Learning Algorithms for Predictive Maintenance

Several machine learning algorithms are particularly well-suited for predictive maintenance. These algorithms analyze historical data, sensor readings, and other relevant information to identify patterns indicative of potential failures.

Regression Models

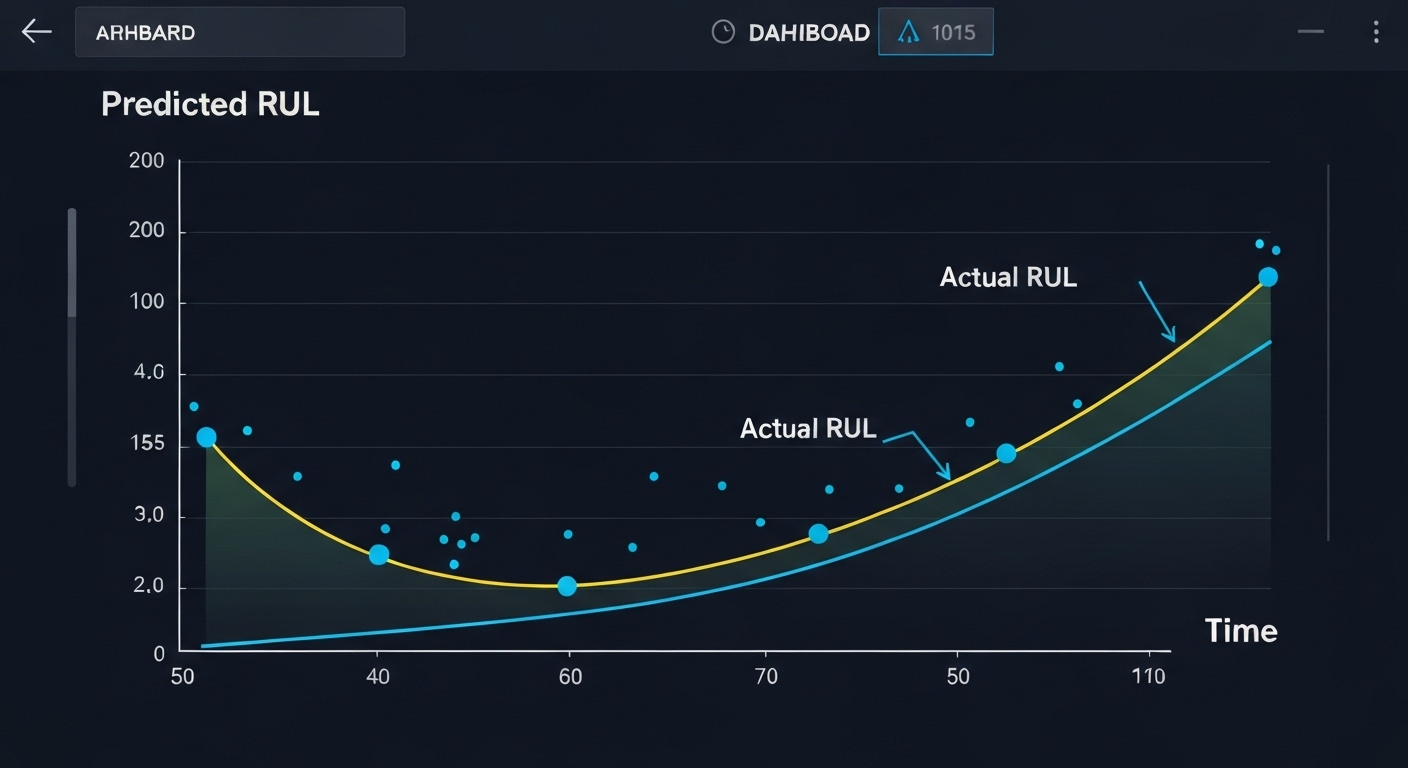

Regression models, such as linear regression and polynomial regression, can be used to predict the remaining useful life (RUL) of equipment. These models learn the relationship between various input features (e.g., temperature, vibration, pressure) and the time until failure.

Classification Algorithms

Classification algorithms, such as logistic regression, support vector machines (SVMs), and decision trees, can be used to classify equipment into different states (e.g., normal, warning, critical). These algorithms learn to distinguish between different failure modes based on historical data.

Clustering Techniques

Clustering techniques, such as k-means clustering and hierarchical clustering, can be used to identify anomalies in equipment behavior. By grouping similar data points together, these algorithms can flag data points that deviate significantly from the norm, indicating potential problems.

Time Series Analysis

Time series analysis methods, such as ARIMA and Kalman filters, are effective for analyzing sequential data from sensors and monitoring systems. These techniques can identify trends, seasonality, and anomalies in time-dependent data, providing valuable insights into equipment health.

Neural Networks and Deep Learning

Neural networks, particularly deep learning models like recurrent neural networks (RNNs) and convolutional neural networks (CNNs), can handle complex and high-dimensional data. They can learn intricate patterns and relationships that other algorithms might miss, making them suitable for complex predictive maintenance tasks. For example, anomaly detection in complex machinery benefits greatly from deep learning’s ability to extract features automatically.

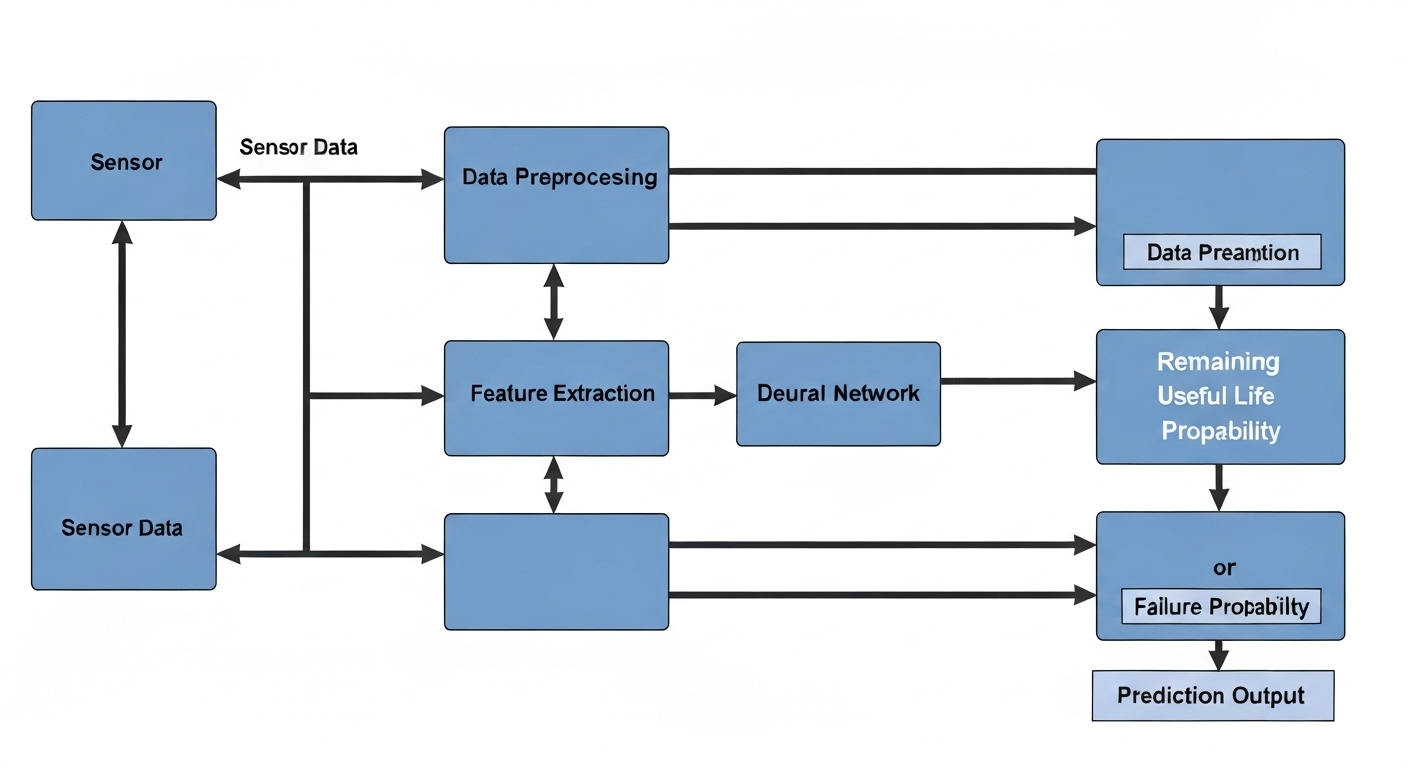

Implementing a Machine Learning Predictive Maintenance System

Implementing a machine learning predictive maintenance system involves several key steps:

- Data Collection: Gather relevant data from sensors, historical records, and maintenance logs.

- Data Preprocessing: Clean, transform, and prepare the data for analysis. This may involve handling missing values, scaling features, and removing outliers.

- Feature Engineering: Extract relevant features from the data that are indicative of equipment health and potential failures.

- Model Selection: Choose the appropriate machine learning algorithm based on the type of data and the specific maintenance goals.

- Model Training: Train the chosen algorithm on the preprocessed data to learn the patterns and relationships between features and failures.

- Model Evaluation: Evaluate the performance of the trained model using appropriate metrics (e.g., accuracy, precision, recall, F1-score).

- Model Deployment: Deploy the trained model into a production environment to provide real-time predictions and recommendations.

- Continuous Monitoring and Improvement: Continuously monitor the model’s performance and retrain it as needed to maintain accuracy and adapt to changing conditions.

Challenges and Considerations

While machine learning for predictive maintenance offers significant benefits, there are also challenges to consider:

- Data Quality: The accuracy of the predictive models depends heavily on the quality and completeness of the data.

- Data Volume: Sufficient data is needed to train effective machine learning models.

- Expertise: Implementing and maintaining a machine learning system requires specialized skills in data science, machine learning, and domain knowledge.

- Integration: Integrating the predictive maintenance system with existing maintenance management systems can be complex.

- Scalability: The system must be scalable to handle increasing amounts of data and a growing number of assets.

Overcoming the Data Gap

One of the biggest hurdles is the lack of readily available labeled failure data. Strategies like synthetic data generation and transfer learning can help bridge this gap, leveraging knowledge from similar systems or simulated environments to enhance model training.

Ensuring Data Security

Data security is paramount. Implementing robust security measures to protect sensitive data from unauthorized access and cyber threats is critical to maintain data integrity and system reliability.

Real-World Applications of Machine Learning in Predictive Maintenance

Machine learning for predictive maintenance is being used in a wide range of industries, including:

- Manufacturing: Predicting failures of critical equipment such as pumps, motors, and compressors.

- Energy: Monitoring the condition of wind turbines, solar panels, and power plants.

- Transportation: Predicting failures of aircraft engines, railway tracks, and vehicle components.

- Healthcare: Monitoring the performance of medical equipment such as MRI machines and CT scanners.

The Future of Predictive Maintenance

The future of predictive maintenance is bright, with advancements in machine learning, sensor technology, and cloud computing driving further innovation. As data becomes more readily available and algorithms become more sophisticated, predictive maintenance will become even more effective and accessible. The integration of industrial IoT (IIoT) devices will further enhance data collection and real-time monitoring capabilities.

For example, NIST is working on standards and guidelines that will further promote the adoption of these technologies. In addition, flashs.cloud offers resources for implementing these systems.

Conclusion

Machine learning for predictive maintenance is a game-changing technology that is transforming how businesses manage their assets and operations. By leveraging the power of data and machine learning, companies can significantly reduce downtime, lower costs, and improve efficiency. As the technology continues to evolve, its impact on industries worldwide will only continue to grow. Embracing machine learning in predictive maintenance is no longer a competitive advantage but a necessity for organizations seeking to thrive in today’s dynamic environment. By proactively addressing potential equipment failures, companies can ensure smooth operations, minimize disruptions, and maximize the lifespan of their valuable assets. Furthermore, the strategic use of machine learning algorithms will lead to more informed decision-making and a more resilient infrastructure.

HOTLINE

+84372 005 899